News

Inteligistics In The News

By Eric Kithinji

•

09 Jun, 2023

In the fresh produce supply chain, solving problems before they happen is key — with positive financial and quality implications as well as a strong sustainability upside.... Read More at https://www.thepacker.com/news/industry/how-fresh-del-monte-using-data-drive-sustainability?mkt_tok=ODQzLVlHQi03OTMAAAGMDArZgyQGMdZqdYX-zq2AD-uhRowc462pgJ8rUf1MD0ajR_dqUd4TekkbDPIvDb6RKtFt2pB3tI9jTA3mCnemgsBJxXg9ElnF6zyo9tNWG08LFKH-Ww

By Eric Kithinji

•

24 May, 2023

Salinas, CA (May 22, 2023) On November 7, 2022, the Food and Drug Administration (FDA) sent a shot across the bow of the fresh foods supply chain when it published the final version of the Food Traceability Rule, also known as FSMA 204. While the rule filled critical traceability gaps in the supply chain by adding requirements for both the first mile (grower to shipper) and last mile (warehouse to store/restaurant), the scramble to fulfill these new requirements and getting knowledgeable guidance has left the industry searching for answers and efficient solutions. Inteligistics is now offering tailored consulting services to help companies identify processes and methods to address this industry dilemma. The intent of FSMA 204, which becomes effective on January 20, 2026, is to allow regulators to identify the source and extent of foodborne illness outbreaks faster to alert the public and avoid wide-spread public health issues. FSMA 204 requires tracing each carton back to the farm, ranch or lot and reporting the information to FDA regulators within 24 hours. Most companies could gather and report the information today at the pallet level, but once a pallet is broken down and distributed, the detailed information is lost. “FSMA 204 doesn’t impose specific requirements on growers such as carton level labeling or electronic records, but as retailers look for their own compliance solutions, they are likely to need participation from their suppliers,” said Rao Mandava, Inteligistics CEO and Chairman. “This will require companies throughout the fresh foods supply chain to work together to develop solutions that work for all parties. It also presents the opportunity for companies to use supply chain digital data systems to gain additional efficiencies, reduce costs and increase revenues. The results from using these advanced technology processes can offset the cost of the regulatory requirements, and can result in a stronger partnership with your trading partners and a profitable return for all.” “Companies must comply with FSMA 204, but they have a choice whether to approach this as a regulatory compliance expense, or as supply chain automation investment with a net bottom line benefit,” said Lawrence Mallia, Inteligistics VP, Digital Transformation. “Based on years of experience working with retailers and suppliers, Inteligistics offers proven advanced technology applications to the stakeholders”. “The ultimate benefit comes from a comprehensive, end-to-end data platform that includes digital data collection and reporting. This information is then applied to advanced technologies such as Artificial Intelligence (AI) and Machine Learning (ML) for efficiency improvements in systems such as cooling assets, cold storage warehouses, retailer inventory picking systems, and even predictive shelf life,” said Mandava. “The key to a successful digital transformation is planning and implementation, including development of a digital twin or parallel system to identify process issues and fine-tune the approach before full implementation,” added Mallia. “We have been advising our clients for years, and now that retailers and suppliers face the uncertainty of complying with FSMA 204, we are offering our consulting services to help them identify and deploy the ‘right’ solution for their company.” For more information Contact Us

By Eric Kithinji

•

24 Apr, 2023

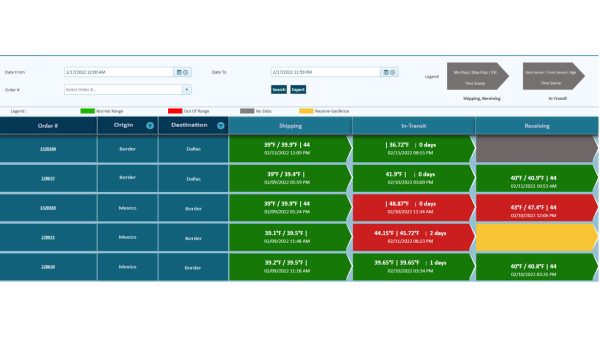

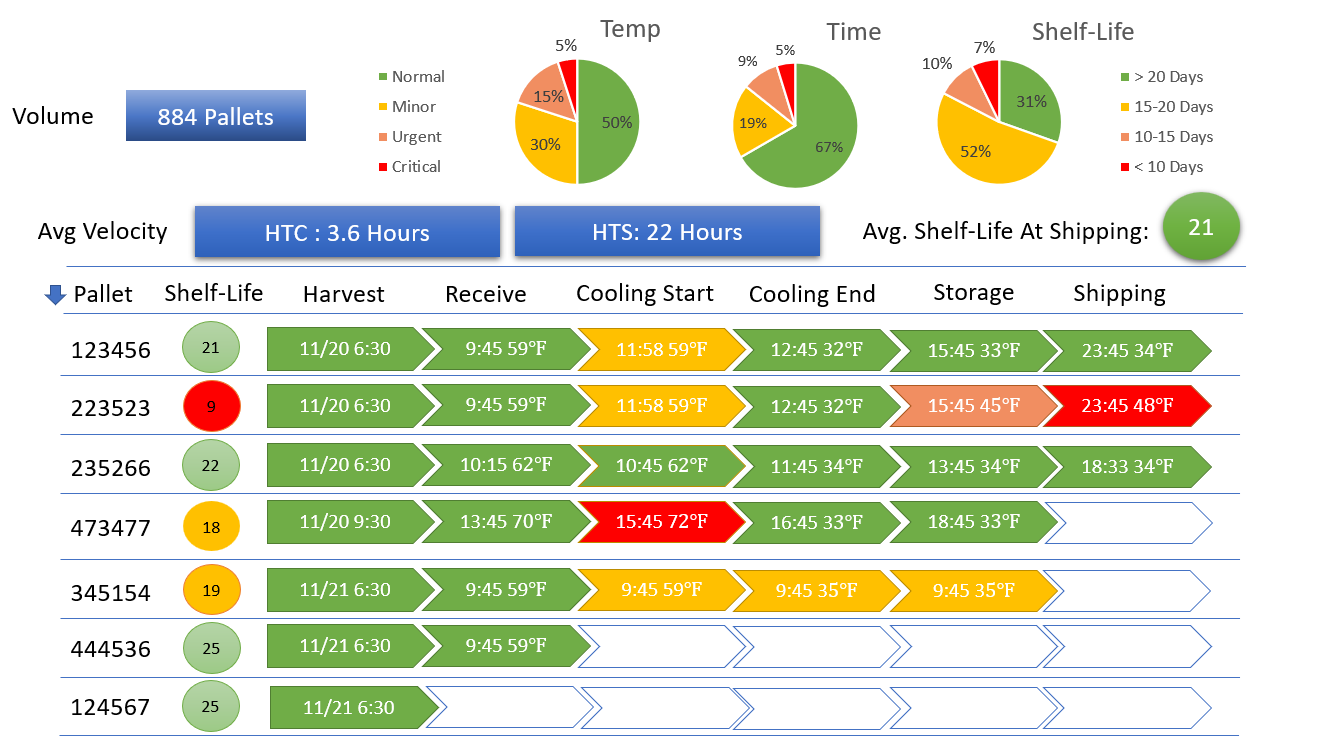

InteliView is a cloud-based, flexible and customizable digital information hub that consolidates data from a variety of IoT and off-the-shelf scanners and sensors, certain APIs and Mobile apps, and ERP, WMS and other data sources to enable companies to make sense of their data in real-time and take action. First-mile to last mile data consolidation, monitoring and reporting provides actionable information to growers, and retailers. Read more..

By THE PACKER STAFF

•

05 Jan, 2023

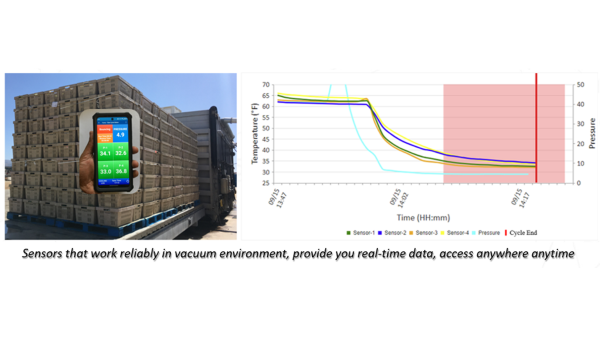

Monitoring and responding to deviations in the cold chain as perishable products go from the field or source to consumers has been demonstrated to be the single greatest factor in ensuring product quality and predicting shelf life, says Inteligistics. The company has announced a new upgrade to its platform that incorporates real-time data from cellular temperature trackers made by Emerson, Delta Trak, Cydeance and others. “We are now able to take the raw data from these wireless sensors that are used throughout cold chain operations and bring this data into our InteliView platform and dashboard,” Rao Mandava, Inteligistics chairman and president, said in a news release. “Combined with digital data collected throughout production and cold storage to the point of shipping, and presented on our cloud-based Inteliview platform, managers can run detailed reports to measure KPIs and highlight and remedy anomalies. “From pharmaceuticals to produce, the shelf life and ROI implications are significant,” Mandava continued. “For example, a recent test of over 2,000 loads of avocados was able to accurately predict shelf life based on time and temperature during transit.” Inteligistics has been bringing end-to-end solutions to monitor and improve efficiency for logistics, supply chain and cold chain management for companies producing and selling perishable products for over a decade, according to the release. Beyond transit temperature and time, Inteligistics uses geo-fences to trigger arrival and departure of pallets, track holding times and inform stakeholders about the load location and status in the supply chain. Integrated with the time and temperature data, this knowledge can lead to significant cost savings, operational improvements and increased product sales, the company said. InteliView is the information hub that takes data from a variety of IoT and off-the-shelf scanners and sensors, certain APIs and mobile apps, and enables companies to make sense of their data in real time and to take action that results in optimizing supply chain and cold chain efficiency, enhancing product quality and increasing profitability, according to the release. The digital data of InteliView can then be leveraged to apply advanced technologies such as artificial intelligence and machine learning for efficiency improvements, shelf-life analysis and predictability, sustainability, waste reduction and traceability. “End-to-end visibility and traceability affects more than food safety,” Dennis Donohue, past president Royal Rose LLC and current executive director of Western Growers Center for Innovation and Technology, said in the release. “Continuous tracking of product temperature and time provides companies with critical information they can use to maintain product quality and predict shelf life. This can result in decreased food waste, increased volumes of saleable product, and revenue optimization opportunities for all entities along the supply chain.”

By Eric Kithinji

•

02 Aug, 2022

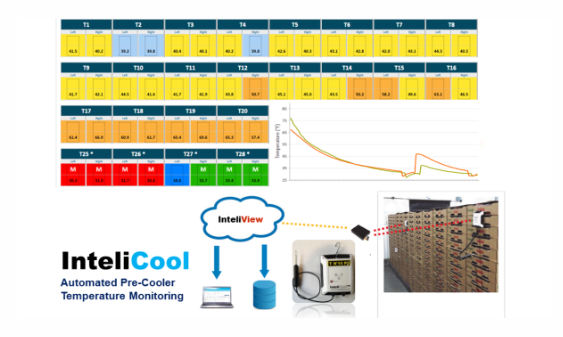

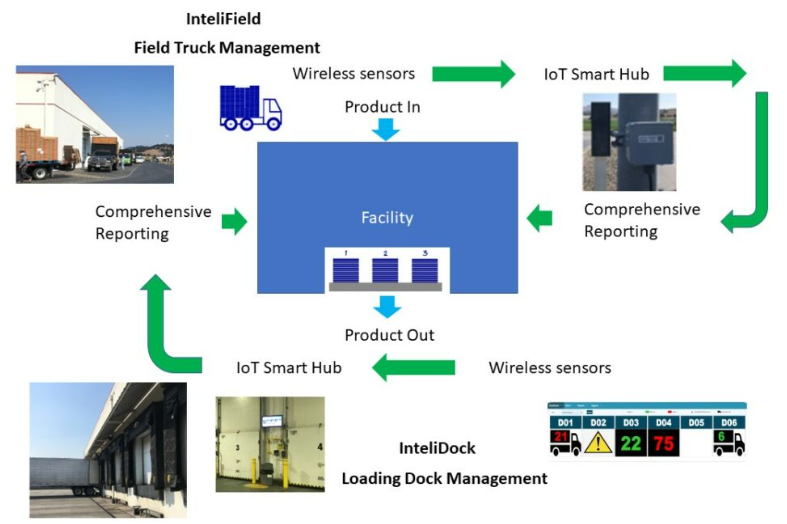

Inteligistics, which has built a suite of smart digital products to monitor and improve efficiency for logistics, supply chain and cold chain management for companies producing and selling perishable products, now brings their technology solutions to bear on a common chokepoint in cold storage facility operations.